Level 1: Process Modeling & Simulation of Mineral Processes in METSIM

This Course is a comprehensive and practical METSIM program tailored for process engineers working on real projects. This program focuses on both foundational knowledge and hands-on application, ensuring that participants can effectively utilize METSIM in their work. The course is a build-up of Level 1 Introductory Course with hands-on application all basics acquired into building complete flowsheets and solving industry related challenges in METSIM.

What will be covered?

- Flowsheeting – CIP/CIL/Any process from your plant

- Crushing & Grinding – PSD setting

- Parameterization of data for existing plants

- Flotation – Pb-Zn/Cu

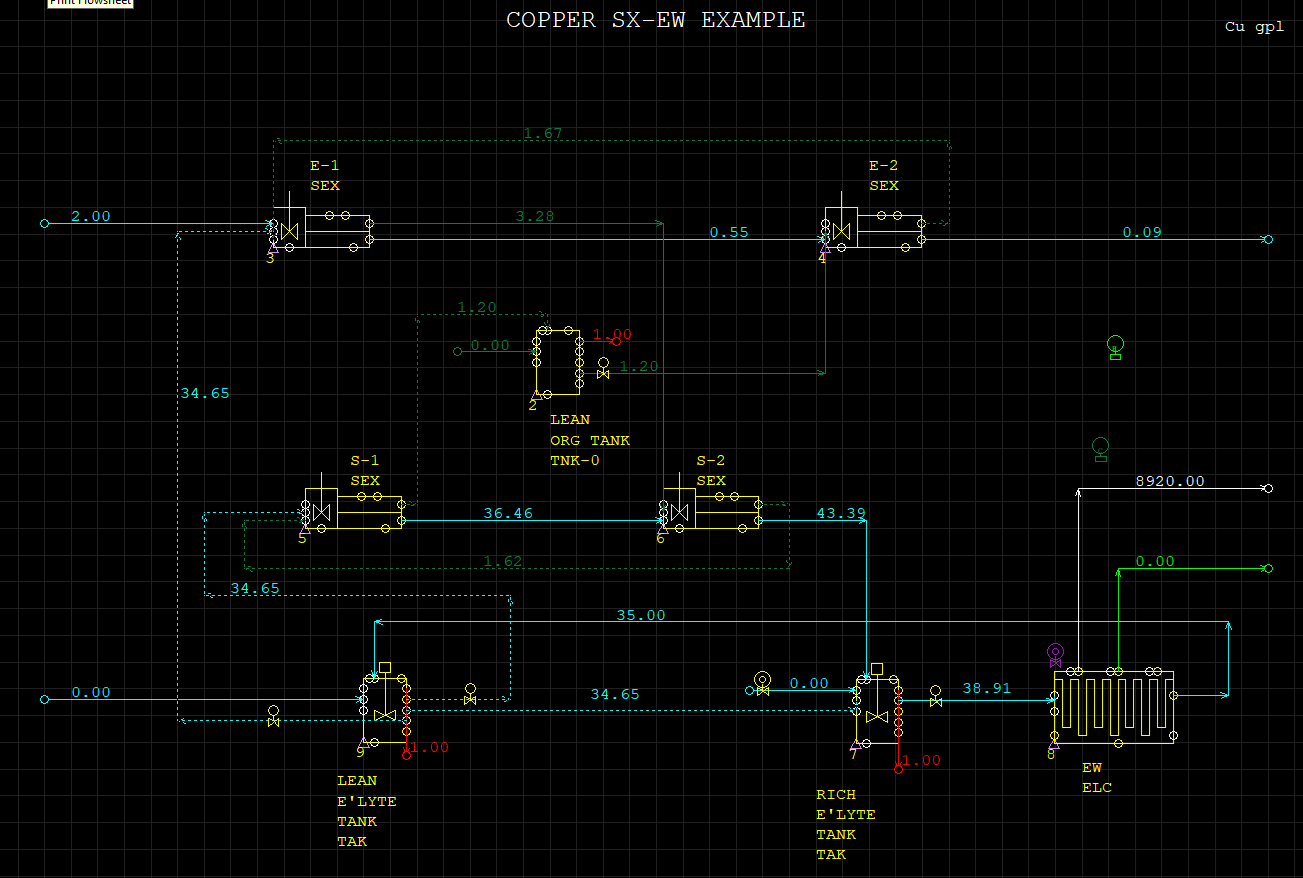

- SX-EW

- DDE & METSIM Silent Mode – Adjusting FEED Composition from Excel

- Component Modeling

- Advanced reporting

Why this Course?

In the hydro-metallurgical industry designing of circuits can be a complex and tedius process. Processes may involve recycle streams some are subject to many changes for example the ores being received may change resulting in changes throughout the circuit. Now if one is using traditional methods of pen and paper or excel they are subjected to many errors. Besides that the time one will take to design or redesign a circuit from crushing to tailings is a lot of which time is money. In some cases huge losses are realized.

![[Downloader.la]-6679d33f40438 (1)](https://www.patfio.co.zw/our-courses/wp-content/uploads/2025/01/Downloader.la-6679d33f40438-1.jpg)

METSIM can be used to construct metallurgical processes quickly. One can quickly make changes when they see the process not working in the Simulation software. It also saves a lot of money as you get to experiment in the simulation environment without actually buying equipment and reagents.

METSIM also has almost everything that one would need in the hydro-metallurgy sector from crushing, milling, leaching, tailings treatment and many other processes. It can handle from mass balances, heat balances, dynamic modeling among other tools making it the go to simulation software for hydro-metallurgical processes.

GETTING STARTED

AFTER DOWLOADING THE WINRAR FOLDER USE THE PASSWORD BELOW

CONFIDENTIAL PASSWORD : Patfio

Model any process of your choice, modeling using real plant data makes it a whole lot fun.

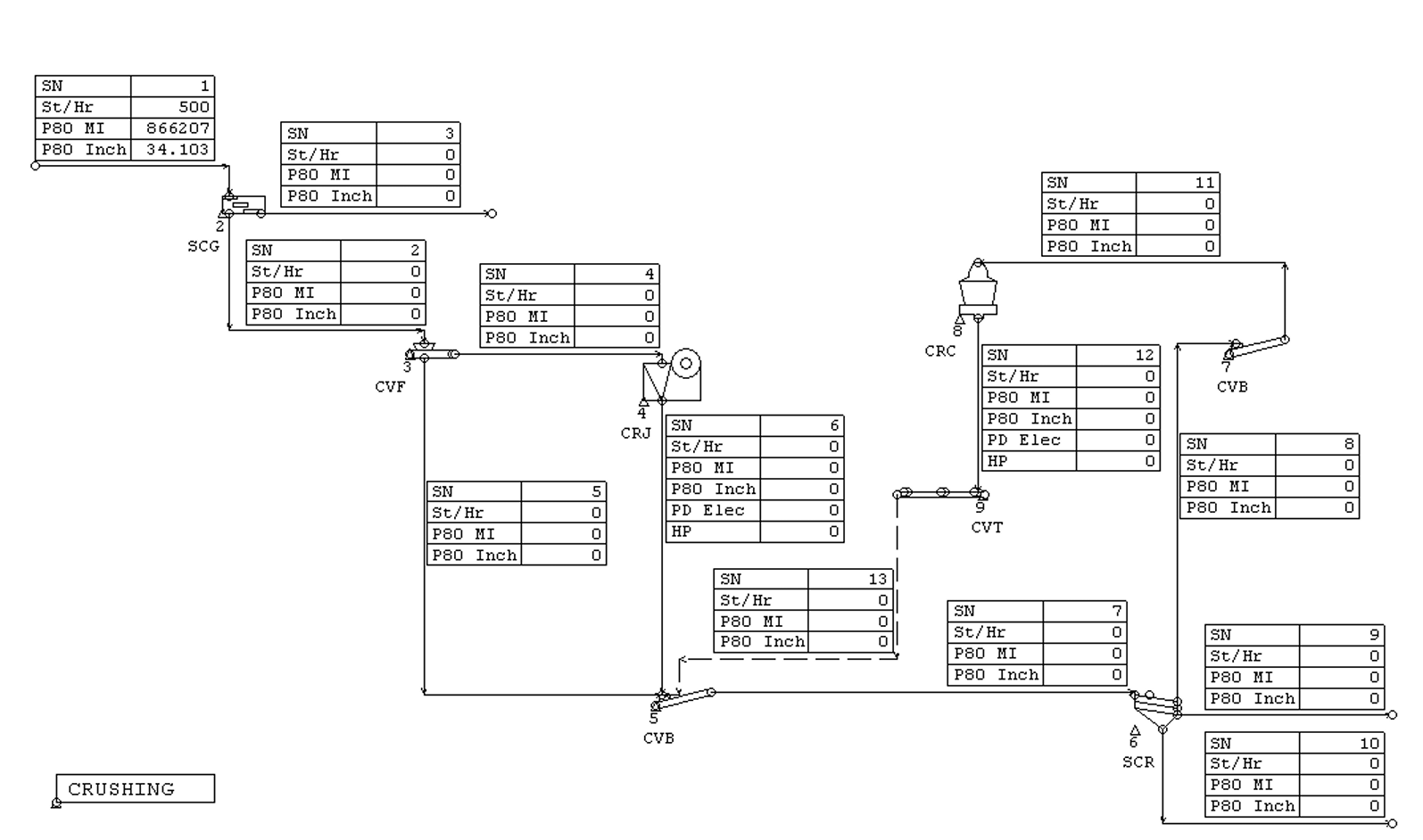

The following example is designed to demonstrate a simple crushing/screening plant in which a circulating load is present. It has been written as though the users have had a small amount of practice with Metsim

1. Bond product P80

2. Bond Discharge P80

3. The residence time.

4. The Herbst cubic & data points method

The following example is designed to demonstrate a simple

crushing/screening plant in which a circulating load is present. It has been

written as though the users have had a small amount of practice with Metsim

ASSIGNMENT COMMINUTION EXAMPLE 5301 – CRUSHING

Download the exercise file "ADJUST FEED COMPOSITION FROM EXCEL" and repeat the exercise following the steps detailed in the file.